Building Canada’s Hyperloop

An Overview:

Having a passion for both Mechanical Engineering and sustainable transportation, joining Waterloop was a no-brainer.

During my first term on the team I worked on advancing Linear Induction Motor technology; experimenting with different core geometries and winding patterns to create a contactless propulsion system to drive the pod.

During testing, a major weak point was the mechanical system to attach the Linear Induction Motors to the pod. With my LIM background, I became the system integration lead, heading development of all mechanical systems integrating with the motors.

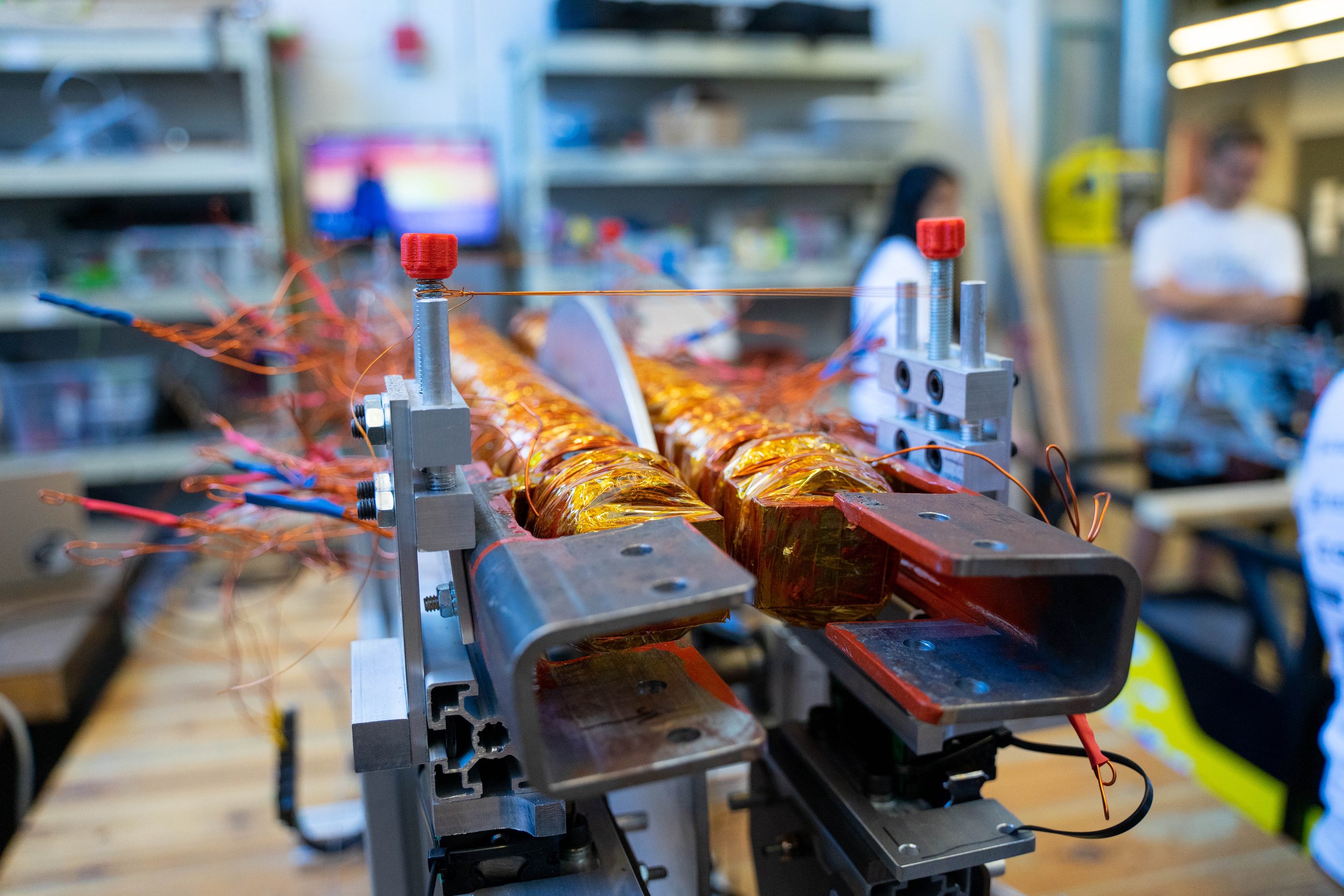

It all began with some R&D. Trying to make Linear Induction Motors go brrrrrrrrrr

Testing motors!

The pod rolls!

It's all coming together...

Finally, a full sub-system test.

Oops.

LIM Blocked Rotor Test Stand

To determine efficiency, static thrust, and 3-phase circuit parameters, I built a test stand for our newly manufactured linear induction motors.

By combining two load cells using a HX711 board configured with Arduino Uno, we examined how thrust changed with different winding patterns (delta vs. wye) and different current/voltage inputs.

Steel-backed aluminum sheet ran on bearings to eliminate resistance & improve repeatability in results

Goose V moves!

Building a moving pod from start to finish required huge commitment from so many team members and a lot of hard work. I learned how challenging coordinating a massive team working on a massive project can be.

(That’s me with the fire extinguisher… blocking the entire frame)